INTRODUCTION

In the past rock was transported by means of hand tramming and wheelbarrows, hopper/rail tramming and diesel-powered trucks. This causes a

disadvantage that it takes too long to transport material and was very

exhausting for men to transport by hand. Tramming by rail or trucks is not very

cost effective at all times as roads and railways need to be built etc.

In the modern days we use conveyor belt systems to transport material

from point A to B. It is fast and you get more production and is cost

effective. A conveyor can be described as an endless moving belt on which

material is placed on and move from one place to another.

The ore transported on the conveyor belt systems in mining operations

to the process plants where ore is processed is the revenue that is generated

for the company to run, so if the belt is damaged or stops unnecessarily the

plant cannot process ore from underground. As an operator of a conveyor belt, it

is of importance that you understand and carry out your duties /

responsibilities to the best of your ability.

DUTIES OF THE BELT OPERATOR:

Adhere to:

1) Starting and stopping procedures

2) Break down procedures

3) Lockout procedures

4) Special instructions

GENERAL DUTIES:

a) Ensure that all safety devices are in good

working order and report any

deficiencies

b) Check for loose, sticking damaged idlers.

c) Remove any obstruction’s that is in the way of the belt and its

components or any obstruction that may cause damage to the conveyor belt.

d) Check condition and operation of the belt scrapers.

e) Check or spillage of material; and built up at the chutes, return

idlers, tail pulley, and head pulley along the length of the conveyor and under

the belt on the return side.

f) Check for any damage to the belt itself.

g) Loading to be on the center of the belt and during operation.

h) Check that no part of skirts or chutes is in contact with the belt

unless it is designed like that.

i) Any equipment at loading stations (tip) not working properly to be

reported to the maintenance staff.

CONVEYOR BELT SYSTEM:

COMPONENTS:

1) A belt to carry the material and transmit the pull.

2) A driving unit to transmit the power to the belt.

3) Idlers and supporting structure (stringers and decking plates)

between the head and tail pulley.

5) Accessories that include devices for maintaining belt tension,

loading, unloading and arrangements for cleaning and protecting belt.

BELT DESCRIPTION:

a) The belt is made up of layers of rubber and canvas

b) The belt is covered with a hardened rubber

c) When the belt tears, it can be repaired:

d) With Belt Clips

e) By Splicing

DRIVERS:

On both horizontal

and incline belt conveyors we make use of electric motors as a power source.

The power from the motor is transmitted to the drive pulley by means of

reduction gearboxes with suitable gear ratios. The motor and the drive pulley

are coupled by means of different types of couplings. Gearboxes are used to reduce the speed and

increase the power of the motor.

Horizontal conveyor

belt requires less power than incline conveyors. That is why horizontal conveyor

belts are driven by one head drive pulley and incline more complex. Tandem

drives normally situated at a point along the length of the belt. Tandem drives

means that two drive pulleys are used on the same belt, either driven by two

identical drive units.

COMPONENTS:

HEAD PULLY:

TAIL PULLY:

LAGGING:

Lagging is situated

on a conveyor pulley. It is rubber that is fitted around the pulley to give a

better grip to the conveyor belt.

SNUB PULLY:

The snub pulleys are positioned so that they facilitate the return of

the conveyor belt directly below the deck plates for safety reasons and the

purpose is to deflect belt.

ANOTOMY OF THE PULLY:

TROUGHING & RETURN IDLERS:

The troughing idlers are design to ensure that the conveyor belt forms

a ‘u’ thus allowing the optimum amount of rock to be moved with the least

amount of spillage. The return idlers are installed to support the return belt.

BELT TENTIONING DEVICE:

In order to drive a conveyor belt with a full load, the belt must be

under optimum tension to prevent it from slipping on the drive pulley. The

ideal tensioning device should possess the following features:

a) It must be capable of applying equal tension across the width of the

belting.

b) It should apply tension gradually.

c) In the event of the load on the belt varying, the applied tension

should be capable of correspondingly increasing or decreasing.

d) The actual value of the applied tension should be known, thus

preventing overstressing of the belting.

e) It should automatically take up any slack or stretch in the belting.

f) An automatic gravity take-up tensioning device is the only

tensioning device which has all the desirable features mentioned above. This

device consists of a weighted loose pulley introduced into the return side of

the conveyor belt at some point. The best position for this device is

immediately behind the driving drum.

CHUTES:

The side of the feed chute onto the conveyor is provided with skirt

plates to prevent rock spillage and to centralize the load onto the center of

the belt.

Ore is discharged

through a chute onto a conveyor at a considerable velocity. This movement of

ore can cause damage to the sides of the chutes. Liners are fitted to the chute to prevent

this damage.

Chutes are used to discharge ore from one conveyor onto another. Using a dead

box design reduces the impact of the moving ore. The ore (burden) collection

reduces the possibility of chute damage.

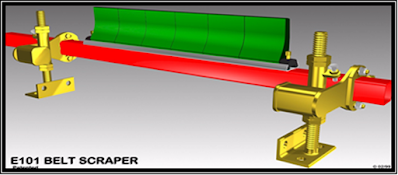

BELT CLEANING DEVICE

/ SCRAPER:

Belt scrapers are normally mounted adjacent to the head pulley and

consists of a rubber blade. Pivoted with a counterweight to maintain pressure

between the blade and the belt. The bolts are most of the time be adjusted on

belt scraper by artisan. Care should be taken that the scraper blade is held

against the belt surface with only sufficient pressure to remove the material.

To prevent excessive wear on conveyor belts, pulleys and idlers, it

is essential to clean the belt after

it has moved around the head pulley and discharged its load.

WATER SPRAYS:

Water loosens and washes the fines sticking to the underside of the

belt by being sprayed onto the belt’s surface before wiping with a rubber

scraper, which assists in releasing the materials from the belt surface.

DECKING PLATES:

Decking plates fitted between the top and the return of the belt will

catch spillage of excess material from the top run. Decking is normally

installed over the entire length of the belt but is especially desirable at the

loading point.

METAL

DETECTORS:

A metal detector is a device that will locate tramp iron, even if it is

buried under ore or other materials, or through a conveyor. The metal detector consists of metal frame

mounted on the conveyor frame under the loaded conveyor. When tramp metal

passes over the metal detector, it will stop the conveyor and activate the

powder marker and siren so as to alert the attendant. The attendant will then

locate the metal and remove it from the conveyor. He will then restart the conveyor belt. Only

found at plant conveyor systems.

INSTRUMENTS:

Weightometers are

installed on to a conveyor belt. Weightometers serve to account for material

travelling on the conveyor belt system; it registers the total weight of

material passing over it, as well as the reading of the tons per hour at any

given time. The Weightometers can be linked to a computer system in the control

room on the shaft.

TACO METER:

The Tacho meter measures the speed of the conveyor belt and anti-slip

detecting device that protects the belt against slip.

Comments

Post a Comment